Where is artificial intelligence headed in the wake of the "new infrastructure" wave?

From infrastructure layouts that drive major social and economic development to the construction of broadband networks that accelerate the prosperity of the internet economy, each bold move by China's infrastructure construction has demonstrated extraordinary power. Now, the "new infrastructure" at the forefront of the times will bring about what kind of tremendous changes to our lives...

After 5G, AI takes the stage!

If 5G is compared to the "vanguard" of communication network infrastructure construction in the "new infrastructure" field, then AI is undoubtedly the "leader" of new technology infrastructure. As early as the Central Economic Work Conference in December 2018, artificial intelligence has been listed as a core component of the "new infrastructure".

During this epidemic prevention and control work, artificial intelligence technologies such as disinfection and sterilization robots, AI temperature measurement systems, and intelligent delivery robots have played a positive role at key epidemic prevention and control points such as hospitals and communities, completely breaking the statement that "artificial intelligence is only a technology that adds icing on the cake". This year, the "new infrastructure" was written into the government work report for the first time, undoubtedly making artificial intelligence even more noteworthy.

From "Vanguard" to "Commander", AI shoulders a greater mission

Currently, the general public's understanding of artificial intelligence is more focused on front-end products and technologies such as robots and voice interaction, and they have little understanding of the underlying support platforms and their functions in serving infrastructure. In fact, with the rapid development of emerging technologies such as big data, cloud computing, and the Internet of Things, The infrastructure attributes of artificial intelligence are gradually becoming apparent, and the grand blueprint of "AI new infrastructure" has already been unfolded.

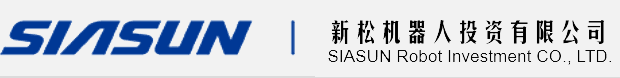

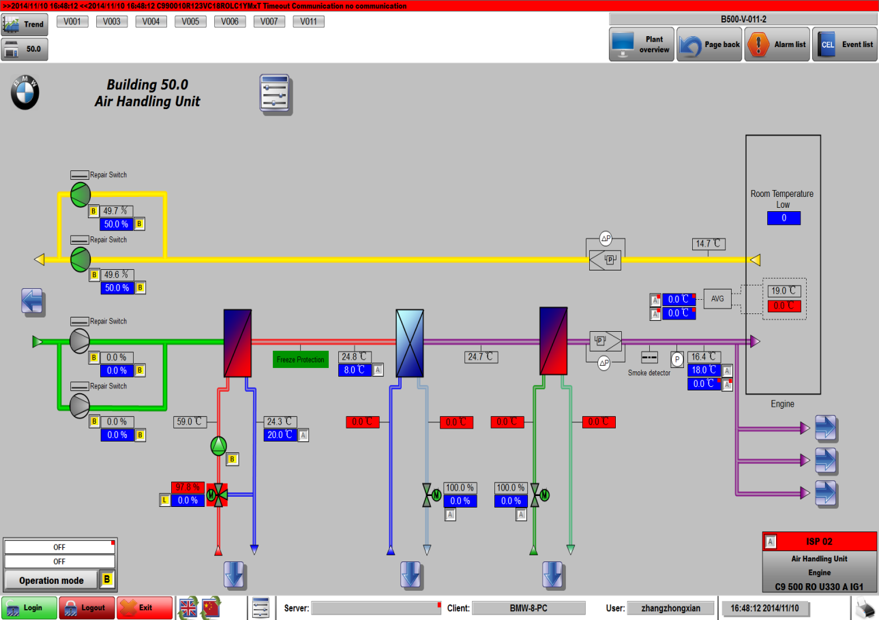

In a well-known automobile production park, the intelligent building automation system designed and built by Siasun is "working tirelessly," staging a new plot of artificial intelligence empowering industrial park management in this world-class automobile manufacturing hall. In addition to having a large factory that includes the complete four major processes of automobile manufacturing: stamping, welding, painting, and final assembly, the industrial park is also equipped with ancillary facilities such as a logistics center, a dynamic testing field, an energy center, a research and development center, and a laboratory.

To achieve precise monitoring and management of such a large-scale building complex and various equipment, traditional technologies are difficult to achieve. In order to provide customers with the safest and most comfortable working environment and ensure that all equipment is in optimal working condition, Siasun integrated various intelligent technologies into the BAS system to build a complete intelligent building automation system.

This intelligent system is like the human "brain command center," remotely monitoring in real time all networked terminal equipment, HVAC equipment, lighting systems, and other subsystems within the factory area through a computer network, achieving the optimal control scheme according to the pre-designed program, and "thinking and analyzing" according to the actual situation to intelligently adjust the comfort and lighting environment of the factory area. At the same time, the system can provide timely warnings of equipment failures and safety hazards, and can "contact" relevant personnel in real time via email or text for maintenance and adjustment, minimizing building energy consumption and maintenance costs in the factory area.

Away from the roar of industrial production, we visit the mysterious "underground world." The underground integrated pipe gallery of Shenyang's North-South Expressway gathers various engineering pipelines such as electricity, communication, gas, heating, water supply, and drainage, and is the city's veritable "lifeline". Siasun is responsible for the detailed design, software development, system integration, and equipment installation of this integrated pipe gallery project. To protect the safe operation of the city's "lifeline" around the clock, Siasun integrated various intelligent monitoring methods in this project to achieve intelligent analysis, linkage warning, and precise fault location.

At the same time, Siasun combined robotics and artificial intelligence technology to create a tunnel "manager" - Pipe gallery inspection robot system . This system has functions such as starlight-level video monitoring, thermal imaging, autonomous charging, anomaly warnings, temperature and humidity detection, and oxygen content detection, and can operate 24 hours a day without interruption. Advanced visual recognition technology can collect and store data from various instruments, and can also identify abnormal states in the pipe gallery. The sensors carried by the robot can perform real-time inspections and alarms on the on-site environment, not only reducing the dangers and burdens of manual inspections, but also improving the reliability of detection.

"Super Employees" Show Their Abilities in the Infrastructure Construction Field

"AI new infrastructure" is the fast lane for artificial intelligence to integrate into various industries, but its technology and experience reserves still need to be improved. Application models like the above case, where artificial intelligence plays the role of "conductor" in the infrastructure construction field, are still in the exploration and development stage as a whole.

However, artificial intelligence cannot be said to be a "new face" in the infrastructure construction field. Even when the maturity of AI technology was not suitable for direct application in infrastructure construction, Siasun has already used a variety of robots and intelligent manufacturing technologies as "mediators" to successfully combine artificial intelligence technology to demonstrate its capabilities in the infrastructure construction field, meeting the urgent needs of traditional industrial upgrading and intelligent economic development.

As a world-class cluster project of "bridges, islands, tunnels, and underground interchanges," the Shenzhen-Zhongshan Link's 8-lane extra-long submarine immersed tube tunnel sets a world precedent. In the welding process of the immersed tube steel shell segments of the Shenzhen-Zhongshan Link, Siasun industrial robots equipped with Siasun expert systems are showing their prowess here. Siasun innovatively integrated visual 3D scanning technology, point laser positioning technology, laser weld seam tracking technology, online robot control technology, and intelligent robot welding technology into the robot welding workstation.

The welding expert system effectively integrates expert wisdom and craftsmanship, Solving problems such as poor workpiece consistency, large processing errors, and irregular weld joint gaps, reducing a large amount of subsequent manual repair and polishing work, both liberating labor and improving work efficiency.

In Dalian, Liaoning, the first batch of unmanned driverless trailers jointly developed by Siasun and Guangzhou Fengshen for application in outdoor intelligent logistics are "running" on different road sections in various workshops Completing material transportation from the in-site workshop to the final assembly workshop. The newly upgraded intelligent trailer has functions such as autonomous operation, autonomous navigation, and safety protection, and can operate normally under complex road conditions and harsh weather such as rain and snow. As a component of the flexible intelligent logistics system, the unmanned driverless trailer realizes flexible logistics operations between workshops, improving the level of intelligent logistics within the company's factory area.

In urban subways, Siasun's newly developed subway ticketing service robot Through passenger voice wave recognition, speech synthesis and processing can be performed to convert text information into standard and fluent speech, making the entire operation more intelligent. The robot seamlessly connects with the subway ticketing backend, and can realize functions such as single-journey tickets, stored-value cards, mobile phone NFC, irregular ticket handling for special-shaped cards, QR code payment, facial payment, business guidance, and information inquiry. In addition, SIASUN provides cloud terminal services for subways, and customers can customize their own knowledge base and database according to their needs.

In the torrent of the intelligent era, if artificial intelligence wants to firmly occupy the leading position of "new infrastructure," it still needs to focus on improving technical capabilities and perfecting technical services. SIASUN attaches great importance to combining the technological development and project application of "AI new infrastructure". On the one hand, it strengthens demand-side guidance and consolidates the public service capacity of artificial intelligence. On the other hand, it continuously outputs flexible, diverse, dynamically iterative, and forward-looking technologies and products around innovative platforms such as SIASUN Central Research Institute's Artificial Intelligence Research Laboratory and SIASUN Shanghai Robotics and Artificial Intelligence Research Institute.

SIASUN will continuously promote technological and model innovation in artificial intelligence, focusing in the era of "new infrastructure" on transforming scientific research achievements into inexhaustible productivity, and inexhaustible productivity into social development power!

Direction, technology, artificial intelligence, intelligence, infrastructure, robots, systems, AI, implementation, equipment